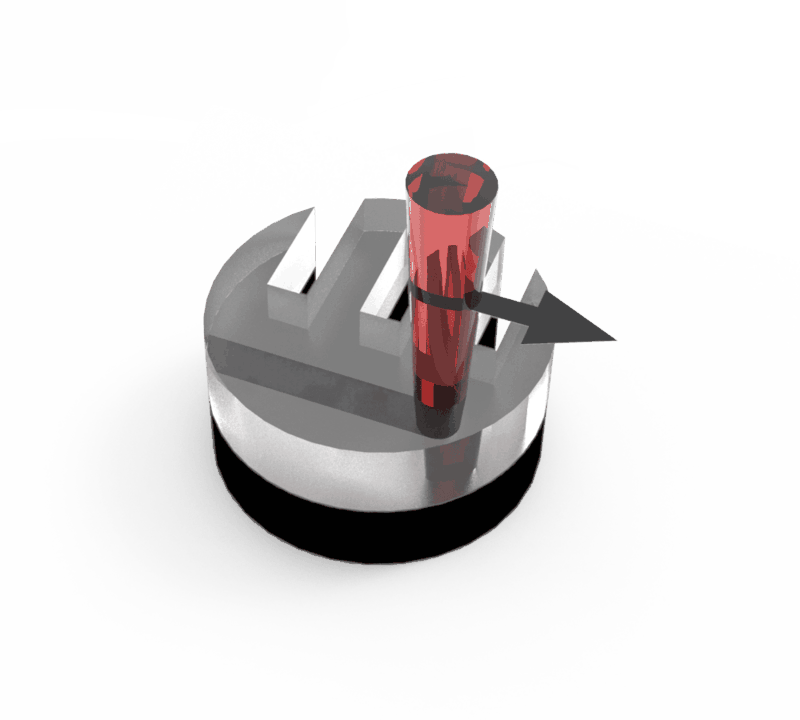

Contour Welding

In the process variant known as contour welding, the laser beam is moved along the weld seam using a suitable motion system. The feed rates usually range between 0 and 500 mm/s. Due to the relatively slow movement of the laser beam, material is only partially heated, melted and welded. Another characteristic of this variant is that the entire welding contour is only traversed once or twice. In addition to axis systems and robots, galvanometer scanners are also used as a movement system. The advantages of contour welding are especially the high flexibility and 3D capability. Since there is almost without exception no movement between the joining partners during the joining process, there is usually no weld seam ejection.