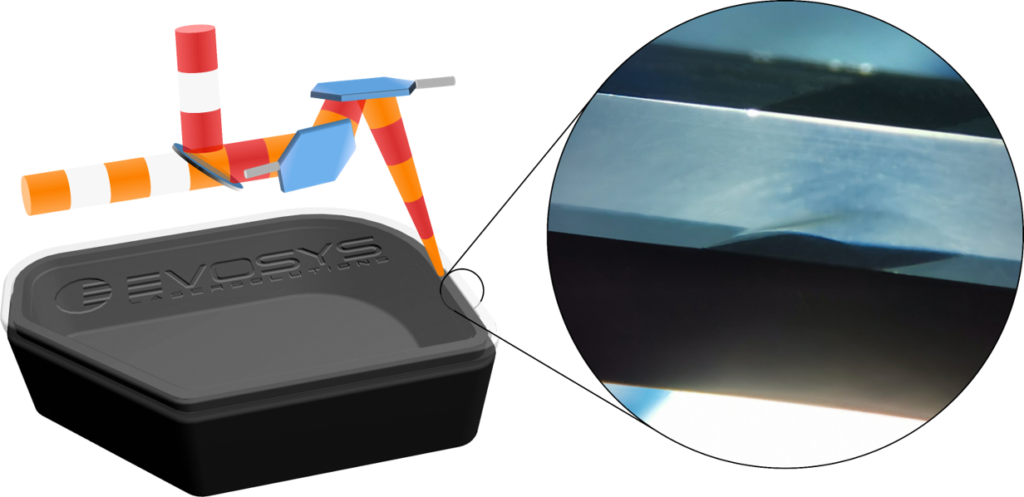

Leak test of laser-welded plastic parts

One of the great advantages of laser welding of plastic is that the weld seams are very homogeneous and therefore leak-tight. The process is ideally suited for achieving IP67 or higher protection levels in a process-safe manner. Even in the prototype phase, however, the question arises of how to pragmatically…