Design layout of the joining zone – Part 2

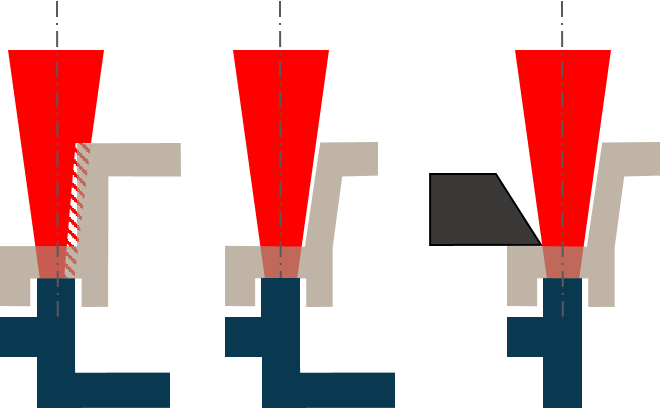

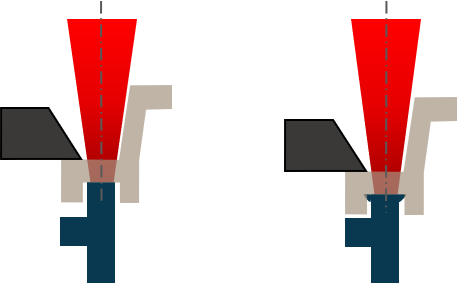

The following criteria are specifically relevant for the individual process variants and must be taken into account accordingly when it comes to the design layout of the joining zone. CONTOUR WELDING-TOLERANCES – As no relative movement of the joining partners to each other can take place in a contour welding…