Thermoplastics for laser welding – Part 3

In most cases, plastics are processed into an end product in a colored state. In the case of consumer goods or on visible components in the automotive sector, for example, aesthetic aspects and specifications must be taken into account. However, functional colorations such as signal colors are also required in certain areas.

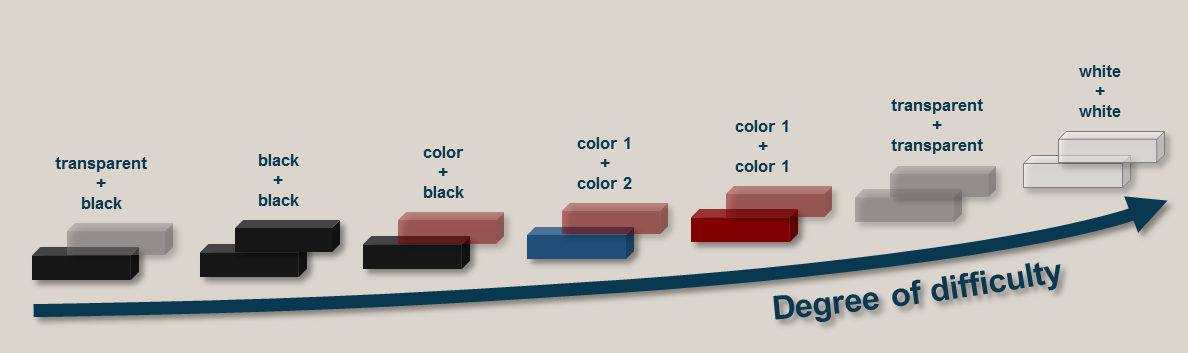

For this reason, colorants are added to the plastics during processing to change the external appearance according to the specifications. Creating a color matrix of laser beam transparent and laser beam absorbing color settings is not possible due to the multitude of variables such as color, plastic, wall thickness, laser wavelength, processing speed, approvals, etc. For this reason, a difficulty level for color combinations was created (see graphic), with which an initial statement can be made for the use of colors for laser plastic welding.

In the case of color additives, a distinction is made between pigments that are insoluble in the plastic and soluble colorants. Both groups have a strong influence on the laser transmission welding of plastics, since they affect the optical properties of the thermoplastic in the near infrared range.

Unlike the colorants, the color pigments are virtually insoluble in the plastic. The color pigments can be inorganic or organic in nature, with the inorganic pigments being completely insoluble.

The most important group among the inorganic pigments are the black pigments. The most important representative is carbon black, which, in addition to being attractive in price, also has positive effects on the properties of the plastic. Carbon black has a sufficiently opaque effect even at low concentrations of 0.5 – 1%. It is excellently suited for coloring the laser-absorbing joining partner, since it absorbs in almost the entire wavelength spectrum.

Another important group among the inorganic color pigments are the white pigments. The most important representatives today include titanium dioxide TiO2, zinc white ZnO and zinc sulfide ZnS. Since white pigments have a highly reflective and scattering effect on the radiation in the near infrared range used in laser plastic welding, components with a strong white color can only be welded with difficulty.

Due to the special requirements of laser transmission welding on the colorings with regard to transmission and absorption for wavelengths in the near infrared range, special additives and colorings have been developed by the plastics producing industry and colorant manufacturers to meet the set requirements. Probably the best-known coloration developed today specifically for laser welding of plastics is IR-transparent black. By superimposing different, conditionally laser-transparent color pigments, an opaque black color impression of a component is created in the visible light range. Unlike other black inks, the coloration created in this way is transparent to wavelengths in the near infrared range.

For color settings that are bright and brilliant, the use of carbon black is not possible. However, with the use of alternative NIR absorbers, almost any color can be adjusted.

Using a range of transparent NIR absorbers, transparent/transparent combinations are possible. Another possibility for joining transparent components is the use of laser wavelengths between 1.6 and 2 μm. In this range, absorption takes place through the plastic itself, so there is no need to add additives. When individually coloring a joining assembly, it is ultimately always necessary to check the feasibility by means of welding tests.