Design layout of the joining zone – Part 3

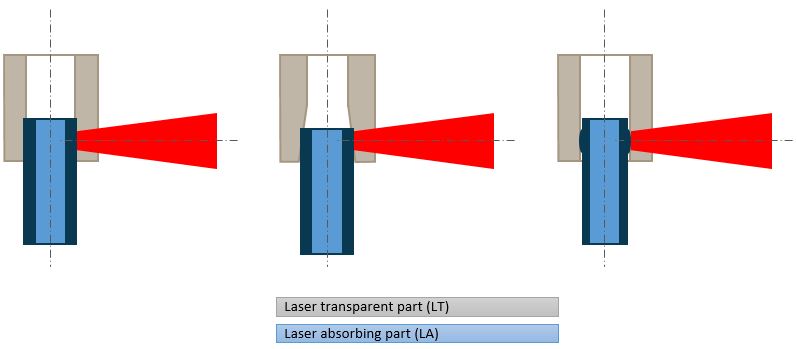

Radial laser welding of radially symmetrical assemblies, such as connectors and tubes, is of particular importance. Unlike the other process variants, no additional clamping force is usually applied due to the joining geometry. Nevertheless, to ensure good thermal contact and sufficient joining pressure in the interface, the components should have an interference fit before welding. In the simplest case, this can be achieved by applying an interference fit to the diameter of the inner joining partner (e.g. a pipe) compared with the outer joining partner, typically in a range of 0.1 mm – 0.2 mm (relative to the diameter). Other possibilities are to provide the inner part with welding rib or to make the contact surfaces slightly conical so that additional application of an axial force also generates radial pressure.

The challenge here is that the assemblies can still be assembled before welding but, taking the tolerances into account, still have a radial overlap > 0 mm in the worst case. The tolerance fields must therefore be sufficiently small, at least in the joining zone. Under no circumstances should the fit of the parts be loose, i.e. there should be radial play in the interface.

Furthermore, sufficient unplasticized material must be provided next to the weld in the axial direction. For example, the weld should not be placed directly on the edge of a pipe end. If the molten material cannot get out laterally during its expansion, this favors radial expansion in the direction of the outer joining partner and thus both the formation of an internal, radial joining pressure and better gap bridgeability.

Finally, the similar general notes should be respected for radial welds as for the other process variants. This means, for example, that there should be no gating points, tool parting lines or other features in the area of the joining zone that could lead to burrs, raised areas or unevenness that would hinder good (thermal) contact of the parts or significantly influence the optical properties.