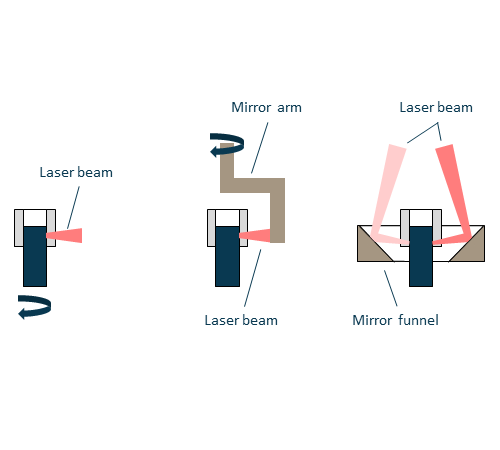

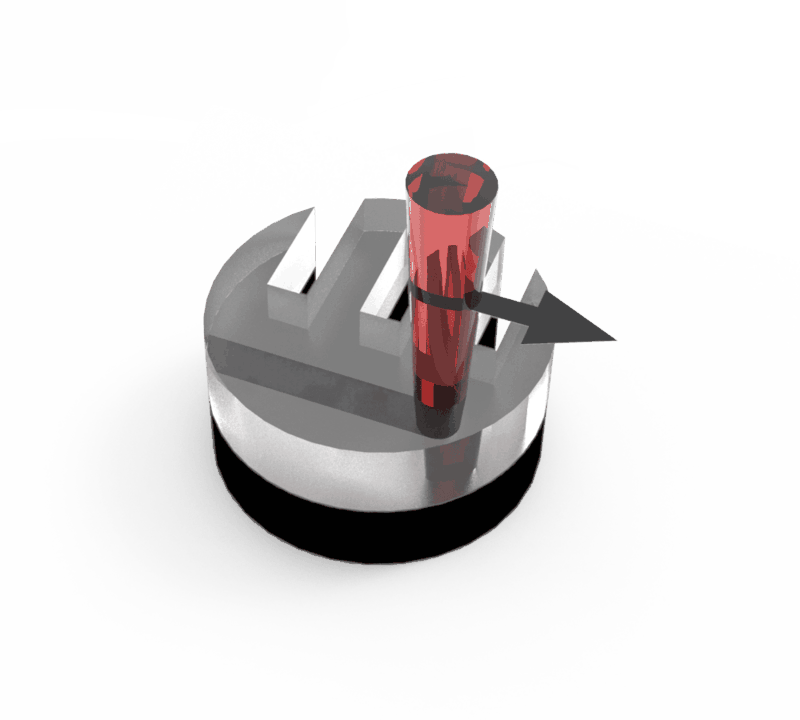

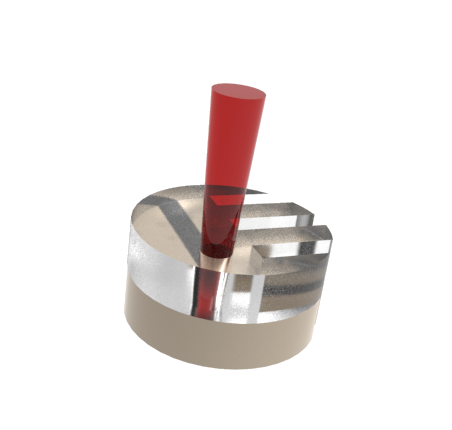

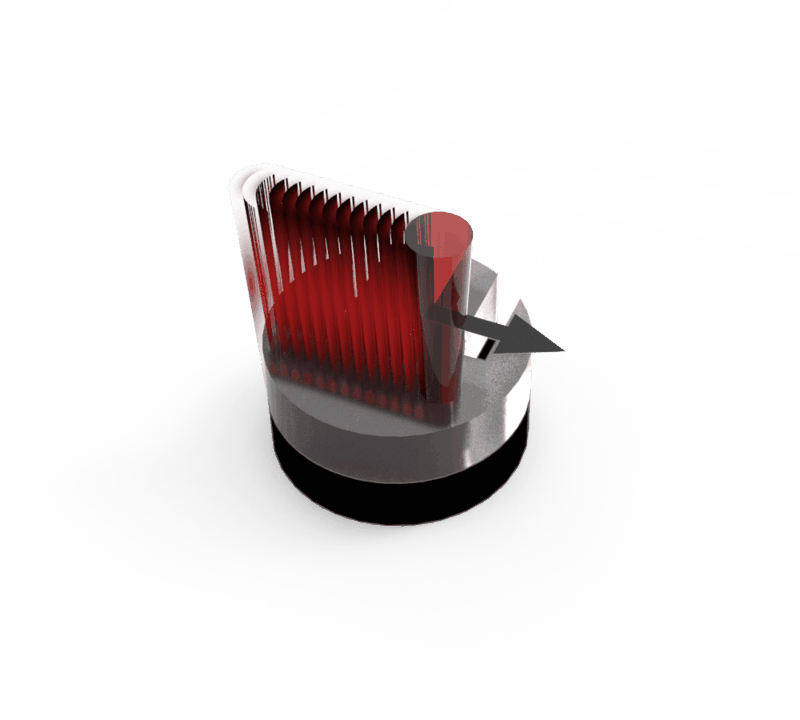

Quasi-simultaneous welding

In so-called quasi-simultaneous welding, the weld seam is repeatedly scanned at high speed with a focused laser beam. The feed rates are usually above 300mm/s up to several meters per second. All areas of the weld seam are heated and melted almost simultaneously (i.e. quasi-simultaneously). Due to the simultaneous melting…